Products

Gland Packing

Die-Formed Rings

Customized Die-Formed Rings manufactured with precision to provide exceptional sealing for demanding applications across industries.

Ropes & Gaskets

Metallic Gaskets

CARBON FIBRE BRAIDED PACKING

SSP - 9100

Service Media and Conditions Acid & Alkali, Caustics, Liquor, Steam, Boiler feed Water, Condensate, DM Water, Fuel Oil, Lube Oil, Solvents, Oil, Gases, Hydrocarbons etc.

| Temperature | 600°C |

| Max Velocity | 25 m/s |

| pH | 0-14 |

EXPANDED PTFE / GRAPHITE PACKING

WITH PURE ARAMID CORNERS

SSP - 8100 Er SSP - 8200

| Temperature | 600°C |

| Max Velocity | 25 m/s |

| pH | 0-14 |

PTFE GASKETS Sr RINGS I SSP

4100 PTFE

| Temperature | -200°C to 260°C (Steam) |

| Velocity | 5 m/s |

| pH | 0 to14 |

EXPANDED GRAPHITE BRAIDED PACKIN

SSP - 3200 I SSP - 3110 INCONEL I SW - 3220 SS

| Temperature | -250°C to 600°C (Steam) |

| Pressure | Upto 450 bar |

| pH | 0 to 14 |

EXPANDED PTFE YARN PACKING

SSP - 4000

Highly corrosive chemicals, ammonia charge pumps, strong as well as weak acid b alkali, chemicals, foodstuffs, pharmaceutical industry applications, drinking water, hydrogen etc.

| Temperature | -200°C to 260°C (Steam) |

| Velocity | 5 m/s |

| pH | 0 to 14 |

GRAPHITE / NON ASBESTOS GASKET

SSP 3100 G

| Temperature | -200°C to 650°C (Steam) |

| Pressure | Upto 300 bar |

GRAPHITE SLEEVE WITH SS-304 EYELETS

SSP 3100 GS

Graphite Packing sleeves are used in many brands of gauge cock, to prevent leakage and to ensure effective operation. They are made from high purity graphite, with stainless steel eyelets, the computer controlled compression, ensure a standard, quality product. A popular application of graphite sleeve is to seal the drain cocks for level gauges, use of graphite sleeves provides smooth and reliable operation of the cocks and high resistance to erosive action of the medium and pollution.

| Temperature | 200°C to 300°C (Non Oxidizing) -200°C to 500°C (Oxidizing) -200°C to 650°C (Steam) |

| pH | 0 to14 (Except Strong Oxidisers) |

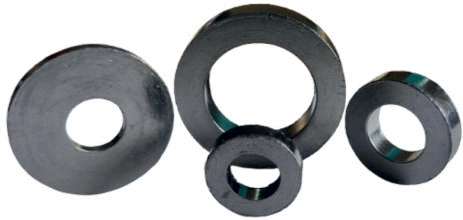

SPW SPIRAL WOUND GASKETS

SSP-3100 G

Spiral wound gaskets are widely used in major process industries as Gasketing solution. These gaskets are made from different filler materials such as PTFE, GRAPHITE and other non-Asbestos materials. The stainless steel cover depends on the required grade in the process fluid such as SS-304/316/INCONEL/MONEL/UNS31803 etc. These gaskets are manufactured as per standard in ASME B16.20 in different pressure classes or in customised form as per demand. Size range starts from 1/2″ to 24″. These gaskets are manufactured with or without inner and outer rings as per the groove and flange sizes. Inner ring and outer ring material composition are defined and supplied as per material grade demand.

| Temperature | 650°C |

| Pressure | Upto 250 Bar Max |

| pH | 0 to 14 |

GRAPHITE TANGED GASKETS

SSP 3100 G METALLIC

Graphite tanged gaskets are used in the chemical and petrochemical industries, in steam systems, and for flange gaskets for piping and machinery. They are often less expensive than MLS gaskets and can seal on rougher surfaces.

| Material | Graphite reinforced with tanged stainless steel |

| Temperature | -200°C to 650°C, depending on the application |

| pH | Vaccum to 140 bar |

| Flexibility | Flexible with high recovery and no aging |

| Impermeability | Impermeable to gases and liquids |

| Compressibility | 45% |

| Recovery | 20% |

PRESSURE SEAL RING REINFORCED WITH SS-304/SS-3161

SS-304/SS-3161 SSP 3100 PSR

- Much better substitute for soft iron gaskets

- Vertical reinforcement of SS wire net provides superb mechanical strength

- Does not damage parent equipment

- Approved by a host of valve makers

| Service Media and Conditions | Superheated and saturated steam, all non-oxidising liquids and gases, hydrocarbons, dyes and chemicals, fuel oil and lube oil etc |

| Temperature | -240°C to 650°C |

| pH | 0 to 14 |

| Max Pressure | 500 bar (static) |

| Applications | Valve bonnets |

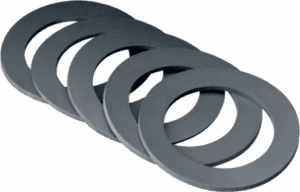

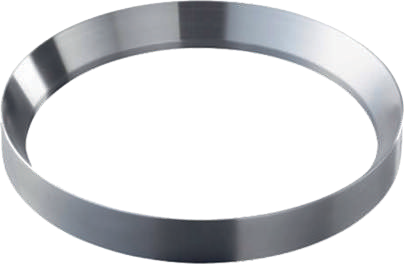

FLEXIBLE GRAPHITE RINGS

SSP — 3100

| Service Media and Conditions | Superheated & Saturated steam, all non-oxidizing liquid & gases, Hydrocarbons, Dyes & Chemicals, Fuel oil & Lube oil etc. |

| Temperature | -200°C to 650°C (Steam) |

| Pressure | Upto 300 bar (static) |

| pH | 14 |

EXPANDED GRAPHITE BRAIDED RINGS

WITH REINFORCED INCONEL WIRE

EXPANDED GRAPHITE BRAIDED RINGS WITH REINFORCED INCONEL WIRE I SSP — 3500 FE

SSP 3500FE Inconel jacketed expanded graphite braided packing, self-lubricating, non-hardening, dimensionally stable and resistant to gases and fluids as well as heat, pressure and chemicals. It’s high temperature flexible graphite and Inconel® filament jacket affords mechanical stability while the advanced construction provides leakage control and high integrity in steam service.- Certified as per API 622, 3rd edition

- Low emission graphite packing (Leakage <100ppm )

| Service Media and Conditions | Superheated and saturated steam, Hydrogen, All liquids & gases, Hot ash, hydrocarbons, dyes and chemicals, fuel oil and lube oil etc. |

| Temperature | 240°C to 650°C |

| Pressure | 550 bar (static) |

| pH | 14 |

SSP 3100.3500 FE (FUGITIVE EMISSION)

SSP 3100.3500 FE

SSP 3100.3500 FE (FUGITIVE EMISSION) BRAIDED GRAPHITE COMBINATION PACKING SET

Combination set consisting of SSP 3500FE Inconel jacketed expanded graphite braided packing as end rings and SSP 3100FE flexible pure graphite die-formed packings as intermediate rings.- The most advanced technology valve packing set designed for high pressure application and extreme performance.

- Certified as per API 622, 3rd edition.

- Low emission graphite packing (Leakage .100ppm) High purity graphite with COU0S100 inhibitor and low detrimental materials like chlorides, fluorides and sulphides, eliminates the chance of decomposition at elevated temperature and formation of oxide, thereby reducing volume loss and increasing tightness.

- The braided end rings are excellent wiper rings, which prevent build up of free graphite/contamination on the valve stem, increase extrusion resistance, pressure resistance and dimensional stability.

- Packing set treated with a high temperature resistant solid lubricating agent to reduce friction even at elevated temperature.

| Service Media and Conditions | Steam, hydrocarbons, hydrogen, catalysts, oils and gases, acid and alkali etc |

| Temperature | -196°C to 540°C |

| Pressure | 425 bar (static) |

| pH | 0 to 14 |

| Applications | Valves |

Our Valued Clients